Have you ever wondered why some beers taste fresh and clean while others have strong or fruity flavors? The key lies in the difference between lagering vs fermenting. Fermenting is the process where yeast converts sugars into alcohol, creating the initial flavors of the beer. Lagering follows fermenting, involving the beer resting at cold temperatures. Around 68.5% of beers worldwide undergo lagering. This step softens the flavors and clarifies the beer, resulting in a smoother drink as chemical changes continue slowly during this cold period.

Key Takeaways

Fermentation is the first step. Yeast changes sugars into alcohol and flavors. This makes the base of the beer.

Lagering comes after fermentation. It means keeping beer cold for weeks or months. This makes the beer clear, smooth, and crisp.

Ale yeast works best when it is warm. It gives fruity and spicy flavors. Lager yeast works better when it is cool. It gives clean and mild tastes.

It is important to control temperature during fermentation and lagering. This helps shape the beer’s flavor. It also stops bad tastes from forming.

A diacetyl rest during lagering is helpful. It removes unwanted buttery flavors. This makes the beer better.

Longer lagering times make beer clearer and more balanced. You need patience to get the best results.

Lagering helps beer last longer. It keeps flavors stable and the beer fresh.

Homebrewers can lager beer in simple ways. They can use a fridge or a cool basement. They should keep the temperature steady and watch the yeast carefully.

Fermenting Basics

What Is Fermentation

Fermentation is a very important part of brewing. To make beer, you first make a sweet liquid called wort. Yeast is added to the wort, and then the process starts. Yeast are tiny living things that eat the sugars in the wort. As they eat, they make alcohol and carbon dioxide. This is how beer gets its alcohol and bubbles.

The fermentation process has a few main steps. Here is a simple list of what happens:

You put the right yeast strain into the cooled wort.

The mix goes into a fermentation vessel, and yeast starts working on the sugars.

You keep the temperature steady so the yeast can do its job well.

After the main fermentation, you move the beer to a conditioning tank. This helps the flavors get better and the beer look clearer.

At the end, you put the beer into bottles, cans, or kegs. Carbonation can happen by itself or be added.

Tip: Always check your beer’s gravity before and after fermentation. This tells you when it is done and how much alcohol is in your beer.

Yeast and Sugar Conversion

Yeast has a special job in brewing. When you add yeast to wort, a chemical reaction starts. The yeast cells break down sugars like glucose and fructose. First, these sugars turn into something called pyruvate. Then, pyruvate changes into acetaldehyde and then into ethanol, which is the alcohol in beer. Carbon dioxide is made at the same time, so the beer gets fizzy.

Scientists have studied this for a long time. They learned that yeast are living cells that grow and help with fermentation. The process works best when there is not much oxygen. Yeast likes to make alcohol when there is a lot of sugar. This is called the Crabtree effect. It helps yeast beat other microbes by making alcohol, which stops other things from growing.

Fermentation Temperatures

The temperature used for fermentation changes how beer tastes. Each beer style uses a certain fermentation technique and temperature. For example, ales usually ferment between 62°F and 75°F (17°C to 24°C). Lagers need colder temperatures, about 46°F to 58°F (8°C to 14°C). Some Belgian beers, like saisons, can ferment at much warmer temperatures, even up to 85°F (29°C).

Here is a table to show the usual temperature ranges for different beer styles:

Beer Style | Primary Fermentation Temperature (°F) | Primary Fermentation Temperature (°C) |

Ales | 62-75 | 17-24 |

Lagers | 46-58 | 8-14 |

Wheat/Belgian | 62-85 | 17-29 |

When you control the temperature during fermentation, you help the yeast make the right flavors. Warmer temperatures can give fruity or spicy flavors. Cooler ones make the beer taste clean and crisp. Picking the right fermentation technique and temperature is important for making good beer.

Lagering Explained

![Lagering Explained]()

What Is Lagering

Some beers taste very clean and crisp. This is because of lagering. Lagering means keeping beer cold for a long time after fermentation. The word comes from German and means "to store." Brewers in northern Bavaria started lagering in the 1300s. They put beer in cool cellars dug into hills. These cellars worked like natural fridges and kept beer fresh. Over time, brewers saw that this made beer taste better and last longer. This is how the lager style began.

A special yeast called Saccharomyces pastorianus made lagering possible. This yeast works at colder temperatures than ale yeast. In the 1500s, a Bavarian law said beer could only be brewed in cold months. This rule helped stop beer from spoiling and made brewers use cold storage. Later, fridges were invented in the 1800s. This let people lager beer all year. Today, lager is one of the most popular beers in the world.

Cold Storage Process

Lagering is not just putting beer in a fridge. You must follow steps to get good beer. Here are the main steps:

First, let the beer ferment at a cool temperature. The yeast slowly changes sugars into alcohol and carbon dioxide.

Next, raise the temperature for a short time. This is called a diacetyl rest. It helps yeast remove bad flavors, like a buttery taste.

Then, lower the temperature again. Store the beer just above freezing for weeks or months. The yeast keeps working slowly. It removes extra sugars and settles out, making the beer clear.

Keep the temperature steady. If it changes, the yeast can get stressed and make bad flavors.

The cold storage step is important for a clean, crisp lager. The beer gets smoother and the flavors become softer.

Tip: Be patient. The longer you lager your beer, the clearer and more balanced it will be.

Lagering Temperatures

It is important to control the temperature when lagering beer. You usually keep the beer between 33°F and 50°F. Many brewers use 34°F to 40°F for the cleanest beer. Some lagers, like German Pilsner, need colder temperatures. Others, like Vienna Lager, do well at warmer temperatures.

Lager Style | Lagering Temperature (°F) | Lagering Temperature (°C) |

German Pilsner | 34-40 | 1-4 |

Vienna Lager | 45-50 | 7-10 |

General Lager | 33-50 | 0.6-10 |

Keeping the temperature steady helps yeast finish its job. It also stops bad flavors from forming. Cold slows down chemical changes, so you need to wait at least a month. This slow, cold process gives lager its clear look and smooth taste.

Lagering vs Fermenting

Sequence in Brewing

When Fermentation Occurs

Fermentation is always the first step in brewing. You add yeast to wort, and the yeast eats the sugars. This makes alcohol, bubbles, and the first flavors. Lagers ferment at cooler temperatures, about 50°F (10-12°C). This helps the yeast stay healthy and work well.

When Lagering Begins

Lagering starts after fermentation is done. You make the beer even colder, around 30°F (-1°C). The beer stays cold for a long time. This is called the lagering period. The beer gets clearer and the flavors become smoother.

Transition from Fermenting to Lagering

Moving from fermenting to lagering is important. Here is what usually happens: 1. Let the beer ferment at a cool temperature. 2. Raise the temperature to about 57°F (14°C) for a short time. This is called a diacetyl rest. It helps get rid of bad flavors. 3. Cool the beer down to near freezing for lagering. 4. Keep the beer cold for at least 35 days. This makes the beer clean, crisp, and clear.

Note: After lagering, filtration takes out yeast and small bits. This makes your lager bright and smooth.

Time and Temperature

Typical Fermentation Duration and Ranges

How long and how warm you ferment changes the taste. Lagers ferment at 50-55°F (10-13°C) until most sugars are gone. A diacetyl rest at 60-65°F (15-18°C) lasts a few days.

Process Phase | Temperature Range (°F) | Temperature Range (°C) | Duration |

Fermentation | 50 - 55 | 10 - 13 | Until active fermentation nears completion |

Diacetyl Rest | 60 - 65 | 15 - 18 | A couple of days |

Lagering (Cold Conditioning) | 30 - 45 | -1 - 7 | Several weeks up to 90 days |

Lagering Timeframes and Cold Storage Temperatures

Lagering takes much longer than fermentation. You keep the beer at 30-45°F (-1 to 7°C) for weeks or even 90 days. Colder and stronger lagers need more time. This slow, cold storage helps flavors mix and the beer get clear.

How Time and Temperature Affect Beer Quality

Time and temperature change the final beer. Cooler temperatures make lagers clean and crisp. Longer lagering removes bad flavors and makes beer clear. If you rush, your lager may taste rough or look cloudy.

Yeast Types

Top-Fermenting Yeast (Ale Yeast)

Top-fermenting yeast is called Saccharomyces cerevisiae. It works best at warmer temperatures, 60-75°F (14-20°C). This yeast floats to the top. It makes beers like pale ales, IPAs, and stouts. These beers often taste fruity or spicy.

Bottom-Fermenting Yeast (Lager Yeast)

Bottom-fermenting yeast is called Saccharomyces pastorianus. It settles at the bottom and likes colder temperatures, 42-54°F (3-12°C). This yeast is used for lagers like Pilsner and Bock. It works slowly and makes beer taste clean and mild.

Aspect | Top-Fermenting Yeast (Ale) | Bottom-Fermenting Yeast (Lager) |

Yeast Species | Saccharomyces cerevisiae | Saccharomyces pastorianus |

Fermentation Temp. | 60 to 75°F / 14-20°C | 42 to 54°F / 3-12°C |

Yeast Behavior | Rises to the top | Settles at the bottom |

Fermentation Time | About a week or more | More than a month |

Flavor Profile | Fruity, spicy, complex | Clean, crisp, mild |

Typical Beer Styles | Pale ales, IPAs, stouts, Belgian | Pilsner, Helles, Bock |

Yeast Behavior in Lagering vs Fermenting

Yeast acts differently in lagering and fermenting. During fermentation, yeast works fast and makes alcohol and flavors. In lagering, yeast slows down but keeps cleaning the beer. It removes bad flavors and helps make the beer clear. The yeast you pick changes how your beer tastes and looks. Lager yeast gives you a crisp, clean beer after a long, cold lagering period.

Flavor Impact

Flavors Developed During Fermentation

Fermentation is when most beer flavors are made. Yeast eats sugars in wort and makes alcohol, bubbles, and flavor compounds. These compounds give each beer its own taste and smell. Some main flavor compounds from fermentation are:

Esters: These make beer smell fruity or floral, like banana or apple. Yeast makes esters by mixing alcohols and acids.

Higher alcohols: These give strong, sometimes spicy or fruity flavors. Too many can taste like chemicals.

Sulfur compounds: These can smell like rotten eggs or cooked veggies. Even a little can change how beer smells.

Aldehydes: These can make beer taste “green” or not finished. Acetaldehyde is common and tastes like green apple.

Organic acids: These add a little sourness and help balance the beer.

The yeast, temperature, and how you ferment change these flavors. Warmer temperatures make more esters and higher alcohols. Cooler temperatures keep flavors mild and clean.

Flavors Refined or Reduced During Lagering

Lagering is when beer rests cold after fermentation. This step helps smooth out and clean up flavors. During lagering, yeast works slowly to fix leftover flavors. Here’s what happens during lagering:

Yeast breaks down extra sugars and off-flavors like diacetyl (buttery) and acetaldehyde (green apple).

Flavors mix and mellow, so beer tastes smoother and balanced.

Cold helps yeast and tiny bits settle, making beer clear.

Hop bitterness gets softer, and all flavors blend for a crisp finish.

You get beer that is clean, smooth, and easy to drink. The longer you lager, the better your beer tastes.

How Lagering vs Fermenting Shapes Final Taste

Lagering and fermenting both change how beer tastes. Fermentation makes the main flavors. You might get fruity, spicy, or strong notes, depending on yeast and temperature. Lagering then smooths out these flavors. It removes harsh tastes and blends everything together.

If you skip lagering, beer can taste rough or not finished. If you rush fermentation, you get too many bad flavors. Doing both steps right gives you clear, clean beer with lots of character. Knowing about lagering and fermenting helps you make beer taste just how you want.

Difference Between Ale and Lager

![Difference Between Ale and Lager]()

Key Yeast Differences

Ale Yeast vs Lager Yeast

You can tell ales and lagers apart by the yeast they use. Here are the main things to know:

Ale yeast is called Saccharomyces cerevisiae. It works at warm temperatures, between 60–78°F (16–26°C). This yeast floats to the top when it ferments.

Lager yeast is called Saccharomyces pastorianus. It likes cooler temperatures, around 42–58°F (9–14°C). This yeast sinks to the bottom during fermentation.

Ale yeast makes more esters and phenols. These give ales fruity and spicy tastes.

Lager yeast works slower and makes fewer esters. This gives lagers a clean and crisp flavor.

Lager yeast is a mix of ale yeast and a cold-loving yeast.

Impact on Flavor Profiles

Yeast changes how beer tastes. Ale yeast makes more esters and phenols. These give ales flavors like banana or clove. Lager yeast works at lower temperatures and makes less of these flavors. Lagers taste clean, crisp, and smooth. Ales have bold and complex flavors. Lagers let the malt and hops stand out with a lighter taste.

Fermentation and Lagering Processes

Primary Fermentation in Ales vs Lagers

Both ales and lagers start with fermentation, but they do it differently. Ales ferment at room temperature. The yeast works fast and makes strong, fruity, or spicy flavors. Lagers ferment at cooler temperatures. The yeast works slowly and makes fewer extra flavors. After fermentation, lagers go through lagering. This is a cold storage step that lasts weeks or months. The beer gets clearer and the flavors become softer.

Use of Lagering and Its Effects

Lagering is what makes lagers different from ales. When you lager beer, you keep it cold for a long time. This helps solids settle and slows down chemical changes. The beer looks clear and tastes clean. Lagering also removes fruity esters and other extras, so the beer feels smooth. Lagers often have a lighter and more refined taste than ales. You get a crisp finish and a refreshing drink.

Tip: If you want a smooth and easy beer, try a lager. If you like bold and fruity tastes, ales are a good pick.

Temperature and Time Factors

Typical Fermentation and Lagering Conditions

Here is a table to show how ales and lagers are different:

Process Stage | Ales (Typical) | Lagers (Typical) |

Fermentation Temp | 65-75°F (warm) | 45-55°F (cool) |

Primary Fermentation Duration | Less than 1-2 weeks | About 1-2 weeks |

Diacetyl Rest | Not usually needed | 1-2 days at 10-15°F above fermentation temp |

Lagering (Cold Conditioning) | Not required | 3-8 weeks at 35-45°F |

Purpose of Lagering | N/A | Mellow flavors, clarify beer, reduce off-flavors |

Influence on Final Beer Quality

Temperature and time change how your beer turns out. Ales ferment fast at warm temperatures. This makes more esters and complex flavors. Lagers ferment slow at cool temperatures. The long, cold lagering step makes beer smooth, clear, and crisp. If you control the temperature, you get a great lager with no bad tastes. The steps make ales bold and cloudy. Lagers are clean, clear, and refreshing.

Note: The difference between ale and lager is not just the yeast. It is also about how you ferment and age the beer. Time and temperature both matter for the final taste.

Impact on Beer

Flavor and Aroma

Both fermenting and lagering change how beer tastes and smells. During fermentation, yeast makes different things that give beer its special flavor. Some of these are diacetyl, which tastes like butter, and acetaldehyde, which tastes like green apples. Sulfur compounds can also show up and smell like rotten eggs or cooked veggies. If you use healthy yeast and keep the beer at the right temperature, these bad flavors go away. This is called a diacetyl rest.

Lagering helps smooth out the flavors made during fermentation. When you keep beer cold for weeks or months, the flavors mix and get softer. Hop bitterness gets less strong, and the beer tastes more balanced. Yeast works slowly in the cold and helps clean up leftover flavors. The yeast, malt, and hops you pick also change the final taste and smell. For example, noble hops like Saaz or Hallertau give a soft, spicy smell. American hops like Cascade add a citrus smell. The water you use and its minerals also change how beer feels and tastes. By changing time, temperature, and what you put in, you make beer taste and smell how you want.

Clarity and Texture

There is a big difference in how clear and smooth beer is if you only ferment it or if you also lager it. Cold fermentation slows down yeast, so you get a cleaner taste and fuller body. When you lager beer, yeast and tiny bits settle at the bottom. This makes the beer look bright and clear.

Lagering makes the beer feel crisp and refreshing.

Cold crashing means chilling beer fast before bottling. This helps proteins and yeast stick together and fall out. It stops haze and gives you sparkling beer.

Warm fermentation can make beer cloudy and rough. Yeast works too fast and leaves more stuff behind.

Keeping the right temperature during both steps is important. If you do, you stop bad flavors and get the clear, smooth beer that many people like.

Shelf Life

You can make beer last longer by fermenting and lagering it the right way. Lagering makes beer clearer and more stable. This keeps beer fresh and tasting good for a longer time. While lagering, yeast keeps working slowly. It removes things you do not want and helps beer get better. The pH drops a little, which helps keep beer safe and less likely to spoil.

Scientists found that how you store beer after these steps matters. If you keep beer cold and away from air, it ages slower and keeps its flavor. Bitter parts in beer break down faster if beer is warm. If you store beer cold, you protect these and keep beer tasting fresh. The right pH, between 4.2 and 4.6, also stops haze and keeps beer safe from germs.

Tip: Always keep your beer in a cool, dark place. This helps it taste good for a long time.

History and Evolution

Origins of Fermentation

Brewing is not new. People have made fermented drinks for thousands of years. At Jiahu in China, archaeologists found old pottery pieces. These pieces are about 9,000 years old. They had chemical signs of honey, rice, hawthorn fruit, and wild grapes. Scientists used special machines to check these drinks. The tools were chromatography and mass spectrometry. They proved these were some of the first fermented drinks. When experts made these old drinks again, they found about 9% alcohol. The taste was like what you would expect from a very old recipe.

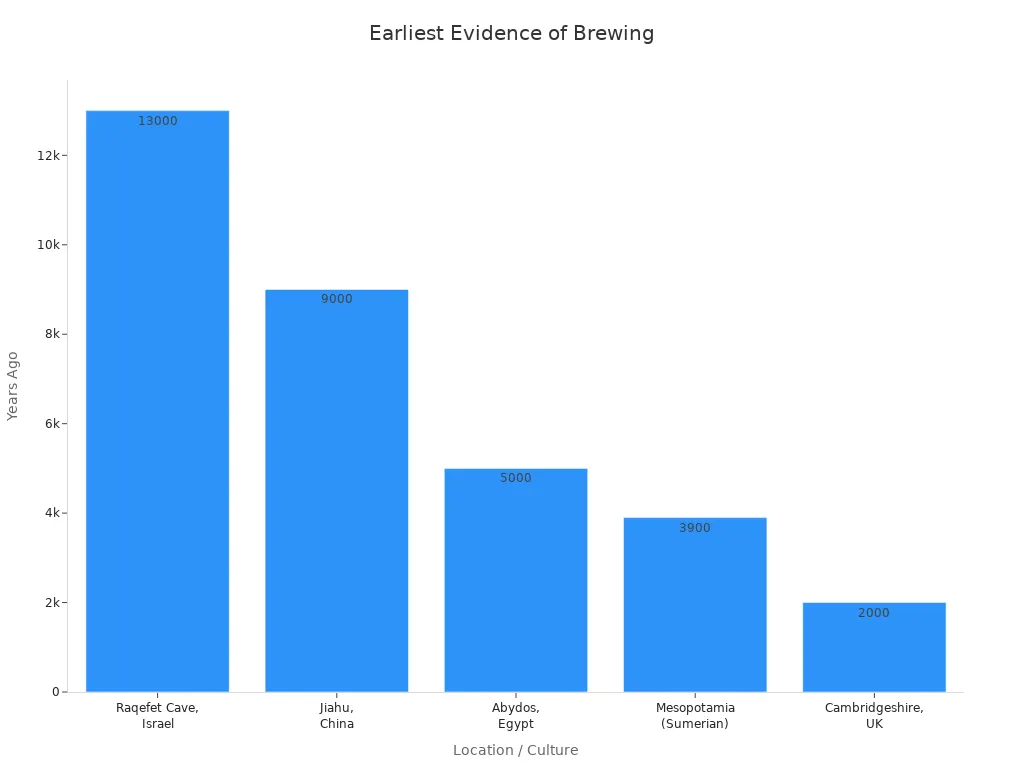

Other places also made beer long ago. In Israel’s Raqefet Cave, beer remains are 13,000 years old. These early beers were thick and mushy. People used them for special feasts. In Mesopotamia, people wrote beer recipes on clay tablets about 3,900 years ago. The Sumerian poem to Ninkasi tells how to make barley beer. It shows beer was important every day. Ancient Egyptians built big breweries, like the one at Abydos. This brewery is 5,000 years old. Even in Iron Age Britain, people made beer. This is shown by beer remains found in Cambridgeshire.

Here is a table that lists some of the oldest brewing evidence from around the world:

Location / Culture | Approximate Date | Type of Evidence | Description |

Raqefet Cave, Israel | 13,000 years ago | Archaeological residue | Beer remains with a thick texture used by Natufians for special feasts. |

Jiahu, China | 9,000 years ago | Archaeological residue (chemical analysis) | Pottery with chemical signs of drinks made from rice, honey, hawthorn fruit, and wild grapes. |

Mesopotamia (Sumerian) | ~3,900 years ago | Written record (poem) | Sumerian poem to Ninkasi with the oldest beer recipe about making barley beer. |

Abydos, Egypt | ~5,000 years ago | Archaeological site | A beer factory from the Early Dynastic Period showing organized brewing. |

Cambridgeshire, UK | ~2,000 years ago | Archaeological residue | Iron Age beer remains found during road work. |

![Bar chart comparing earliest archaeological and historical evidence of brewing across different ancient cultures.]()

Old texts and objects from Mesopotamia show beer was important. The Epic of Gilgamesh and the poem to Ninkasi both talk about beer. These records prove people already knew how to brew well and taught others.

Birth of Lagering

Lagering did not start with the first brewers. It began later in Europe, mostly in Bavaria, during the Middle Ages. Brewers saw that beer kept in cool caves or cellars tasted better and stayed fresh longer. The cold slowed down yeast and bacteria. This helped keep beer from going bad.

Bavarian brewers used a special yeast that liked cold. This yeast is called Saccharomyces pastorianus. It sank to the bottom and worked well in the cold. By keeping beer just above freezing, they made it clear, crisp, and smooth. Soon, lagering became very important in Germany and spread to other places.

Fun Fact: The word "lager" comes from German and means "to store." Thanks to careful storage and yeast, we have the lagers we enjoy today.

Now, lagering is a science. Brewers use exact temperatures and timing for every batch. This makes sure the beer is clean and balanced. Lagering changed beer forever. It gave us new tastes and styles that people still love all over the world.

Choosing a Process

Beer Styles

When you choose how to brew your beer, you first need to think about the style you want. Ales and lagers use different processes and give you different flavors. If you want a beer with bold, complex flavors, you should look at ale styles. Ales use top-fermenting yeast that works best at warmer temperatures, usually between 60°F and 75°F. This yeast creates fruity, spicy, or even chocolatey notes. You can find these flavors in pale ales, IPAs, brown ales, stouts, and wheat beers like German Hefeweizen. These beers often finish faster, so you do not have to wait long to enjoy them.

Lagers use a different method. They rely on bottom-fermenting yeast that likes cooler temperatures, around 45°F to 55°F. After fermentation, lagers need a long cold storage step called lagering. This process gives you a beer that tastes clean, crisp, and smooth. Popular lager styles include pale lagers, amber lagers, bocks, and dark lagers. Lagers often look clear and have a lighter taste. If you want a beer that is easy to drink and refreshing, a lager is a great choice.

Note: Some ales can use cold conditioning, and some lagers may ferment a bit warmer. This shows that brewing is flexible, and you can experiment with different methods.

Here is a quick table to help you match beer styles with their main brewing process:

Beer Style | Main Process | Typical Flavor Profile |

Pale Ale, IPA | Fermenting (Ale) | Fruity, hoppy, complex |

Stout, Brown Ale | Fermenting (Ale) | Roasty, chocolatey, rich |

Wheat Beer | Fermenting (Ale) | Spicy, fruity, cloudy |

Pale Lager | Lagering | Crisp, clean, light |

Amber/Dark Lager | Lagering | Malty, smooth, balanced |

Bock | Lagering | Strong, malty, smooth |

Homebrewing Tips

If you want to brew at home, you need to decide if you want to make an ale or a lager. Each process has its own steps and tricks. Here are some tips to help you get the best results:

Pitch your yeast into wort at the right temperature. For lagers, use cold wort to avoid unwanted fruity flavors.

Watch your fermentation closely. You can speed up the process by raising the temperature a little in the middle, but only if your yeast can handle it.

Always do a diacetyl rest for lagers. Raise the temperature near the end of fermentation to help remove buttery off-flavors.

Be patient with lagers. They need several weeks of cold storage to become clear and smooth.

Remember, ales ferment faster and at warmer temperatures. You can enjoy them sooner than lagers.

Use a two-stage fermentation for lagers. Move your beer to a new container before lagering to keep it clean and clear.

Keep your fermentation temperature steady. Lagers need cooler temperatures, usually between 38°F and 60°F.

Try creative ways to keep your beer cold. You can use a fridge, a swamp bath, or even a cool basement.

Do not add more yeast when you move your beer to a new container. Enough yeast will stay behind to finish the job.

Taste your beer as it ages. Lagers get better with time, but too much aging can make them lose freshness.

Tip: Choose your yeast based on the style you want. Lager yeast needs more cells and colder temperatures. Ale yeast works faster and gives you more flavor.

By thinking about your favorite beer style and following these tips, you can choose the right process and make a beer you will love.

Lagering and fermenting each play a special part in brewing. Fermenting uses yeast to turn sugars into alcohol and flavors. Lagering comes next, using cold temperatures and time to make beer clear and smooth.

Always control your temperatures and watch your yeast.

Choose the right yeast strain for your style.

Be patient—good lagers need time to develop crisp flavors.

Understanding these steps helps you brew better beer and pick styles you enjoy. Try different methods and see how each process shapes your favorite drink!

FAQ

What is the main difference between lagering and fermenting?

Fermenting turns sugars into alcohol and flavors using yeast. Lagering happens after fermenting. You store the beer cold to make it clear and smooth. Both steps help you get the taste and look you want in your beer.

Can you skip lagering when brewing beer?

You can skip lagering if you make ales. Lagers need this step for a clean taste. If you skip lagering with lagers, your beer may taste rough or cloudy. Always follow the right process for your beer style.

Why does temperature matter so much in brewing?

Temperature controls how yeast works. Warm temperatures make yeast work fast and create fruity flavors. Cold temperatures slow yeast down and give you a clean, crisp taste. You must keep the right temperature for the beer style you want.

How long should you lager your beer?

Most lagers need at least 4 weeks of cold storage. Some strong lagers need up to 3 months. The longer you lager, the clearer and smoother your beer becomes. Patience gives you better results.

What kind of yeast do you use for lagers and ales?

You use bottom-fermenting yeast for lagers. This yeast works best in the cold. For ales, you use top-fermenting yeast. It likes warmer temperatures and makes more fruity flavors. The yeast you choose changes your beer’s taste.

Does lagering make beer last longer?

Yes, lagering helps beer last longer. Cold storage lets yeast clean up unwanted flavors and makes beer more stable. Your beer stays fresh and tastes good for a longer time if you lager it properly.

Can you lager beer at home without special equipment?

You can lager at home if you have a fridge or a cool basement. Keep your beer cold and steady, between 34°F and 40°F. Use a thermometer to check the temperature. You do not need fancy tools, just patience and care.