In the current food industry, packaging design has long been not only a means to protect products, but also a comprehensive embodiment of brand value, user experience and environmental protection concept.

Packaging Awards were announced at the recently concluded 2024 Japan Packaging Show. From the award-winning products, we once again see that environmental protection and sustainability, function + experience, fun and interactive packaging have become the mainstream direction of food packaging innovation.

Each Japan Packaging Awards has three categories: "Star of Japan", "Packaging Technology" and "Packaging Category", covering the outstanding work of the Japanese packaging industry in technology, design and sustainability dimensions over the past year.

![828b09a28668fb94fd4b98ebb8a46fb 828b09a28668fb94fd4b98ebb8a46fb]()

Foodaily has selected 6 products from 263 award-winning cases in the past two years to interpret them from the aspects of environmental protection, technology, function and user experience, hoping to provide new ideas for packaging design for the domestic food industry.

01 Dual drive of environmental protection and innovation, from design to technology innovation

Environmental protection has always been a hot topic in the field of packaging design. According to the 2021 Global Consumer Insights Report, 55% of respondents around the world intend to buy or use environmentally friendly packaging or goods with relatively less packaging materials. In the past two years, the theme of environmental protection runs through the winning works of Japan Packaging Award. In these cases, we can not only see the breakthrough in environmentally friendly materials and process technology, but also find the design ingenuity of highlighting details, so that plastic reduction and environmental protection and user experience can meet.

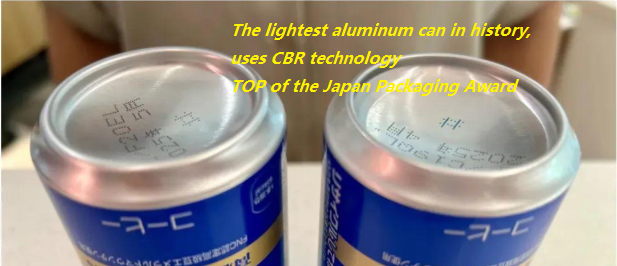

By making aluminum cans the lightest in the world, the strength has increased

Under the trend of low-carbon packaging, the miniaturization and thinness of packaging and the sustainability of packaging materials have become an important development trend. Among them, aluminum cans are widely used in the food and beverage industry because of their low cost, strong plasticity and sustainability. Many enterprises use the ductility of metal to thin the side wall of the tank, which not only saves materials but also realizes the lightweight of aluminum cans.

However, the thinning of aluminum cans can have an impact on the strength of the packaging. But Toyo Can has developed "the world's lightest aluminum beverage can" to achieve lighter body, but also to ensure that the strength does not drop.

It is understood that this beverage can reduces the material use by 13%, the single can weight is only 6.1 grams, compared to the same size of the traditional beverage can weight reduction of 0.9 grams, and through CBR technology to ensure the strength and durability of the metal, suitable for 190 ml capacity SOT (Stone-on-Tab). The aluminum can has been used in some products of Coca-Cola's coffee brand Georgia, and mass production began in Japan's Kanto region in August.

![1512effc67559390d9e73d43c5ed55b 1512effc67559390d9e73d43c5ed55b]() The coffee beverage can on the right uses CBR technology

The coffee beverage can on the right uses CBR technology

Foodaily understands that CBR (Compression Bottom Reform) is an innovative technology developed by Toyo Can-making, which can provide higher compressive strength of tank bottom compared to traditional can-making technology. The mass and weight of DWI aluminum cans (a two-piece can manufactured by a stretch thinning process) and aTULC aluminum cans can be reduced, while also reducing the use of aluminum materials and reducing greenhouse gas emissions.

aTULC is a "dry molding" technology that minimizes water and energy consumption. Combined with this technology, it can also provide environmentally friendly advanced packaging containers and canning systems. In addition to 190 ml cans, CBR is also used to produce 350 ml and 500 ml aluminum cans.

![8a7b967ed34f69100fbf418d25e95fe 8a7b967ed34f69100fbf418d25e95fe]()

This lightweight design not only saves materials, but also reduces greenhouse gas emissions by about 8%. For the mass production of beverage industry, it has great environmental significance. According to Toyo Can, if the technology can be widely used in aluminum beverage can packaging around the world, it can reduce greenhouse gas emissions by about 40 thousand tons per year. This is a major advance in packaging technology in the pursuit of lightweight and sustainable development.

China's "14th Five-Year Plan" has made innovative design, green environmental protection and digital application the development focus of the packaging industry. In recent years, Foodaily has reported on the interpretation of packaging awards, which clearly confirms these trends.

Through the winning works of the Japan Packaging Award, we can also see that the packaging design not only pursues visual appeal, but also pays more attention to the combination of functional and environmentally friendly materials. In the future packaging design, innovation centering on improving user experience and brand value will occupy a prominent position.

Do you have a packaging idea you like? Welcome to contact us online to discuss

The coffee beverage can on the right uses CBR technology

The coffee beverage can on the right uses CBR technology