In today’s fast-moving beverage industry, packaging plays a defining role in product quality, sustainability, consumer experience, and brand perception. While many packaging formats have been introduced over the years—ranging from PET bottles to glass, cartons, and pouches—aluminum cans continue to lead the global market, especially for soft drinks, energy beverages, juices, teas, and even premium water brands. As sustainability and convenience become more important to consumers, aluminum cans are experiencing renewed demand and innovation.

1. The Evolution of Aluminum Cans in Beverage Packaging

Aluminum cans first gained prominence in the mid-20th century as a lightweight, durable replacement for steel cans and glass bottles. Over time, advances in metallurgy, manufacturing processes, and coating technology transformed them into one of the most optimized packaging formats in the world. Today, billions of aluminum cans are produced annually, and the packaging remains a favorite among beverage brands for its long shelf life, high recyclability, and economic efficiency.

The rise of ready-to-drink beverages—from sparkling water to cold brew coffee—has further strengthened the role of aluminum cans. Their ability to preserve carbonation and flavor stability gives them a performance advantage over many alternative materials, while their sleek, modern appearance appeals strongly to younger consumers.

2. Key Advantages of Aluminum Cans in Modern Beverage Packaging

Exceptional Recyclability and Sustainability

One of the most compelling reasons aluminum cans dominate the marketplace is their near-infinite recyclability. Unlike plastics, which degrade in quality each time they are recycled, aluminum retains its structural integrity indefinitely. This means a recycled can could be turned into a new beverage can within as little as 60 days.

Key sustainability advantages include:

100% recyclability without material loss

High scrap value, making recycling economically viable

Lower carbon footprint during transport and manufacturing

Significant energy savings, as recycling aluminum uses only ~5% of the energy required to produce new aluminum

For beverage companies aiming to meet global sustainability commitments, aluminum cans offer one of the most environmentally responsible packaging solutions available today.

Superior Product Protection

Aluminum cans provide exceptional protection for beverages because they are:

Opaque, preventing UV light exposure that can degrade flavor

Airtight, preserving carbonation and freshness

Non-reactive when coated with food-grade liners

Durable, reducing breakage during shipping and storage

In particular, drinks like beer, sparkling water, and energy beverages benefit from aluminum’s ability to preserve carbonation and maintain consistent flavor. Light-sensitive beverages—such as fruit juices, teas, and certain health drinks—also remain stable for longer in aluminum packaging compared with transparent plastics or glass.

Lightweight and Transportation Efficient

Transportation is a major cost factor in beverage production. Aluminum cans are considerably lighter than glass bottles and take up less space when palletized. This means:

More units can be shipped at once

Lower fuel consumption

Lower transportation costs

Reduced environmental impact

These advantages are critical for beverage brands distributing products nationally or internationally.

Convenient and Consumer-Friendly

Aluminum cans are widely appreciated for their consumer convenience:

Quick to chill

Easy to carry

Single-use, portable format

No risk of breakage

Ideal for outdoor events, travel, and sports

Modern consumers—especially younger demographics—prefer portable, ready-to-drink formats. Cans meet this need perfectly while also supporting branding through high-resolution, 360-degree printing.

High Branding and Design Flexibility

A beverage can is not merely a container—it’s a powerful visual marketing tool. Aluminum cans support various printing technologies, including:

This flexibility allows brands to design packaging that stands out on shelves and communicates identity instantly.

3. Types of Aluminum Cans Used in Beverage Packaging

Standard Two-Piece Cans

Most beverage cans are produced using a two-piece drawing-and-ironing process. This format includes:

A seamless body

A separate can end (lid)

These cans are ideal for carbonated drinks due to their excellent strength-to-weight ratio.

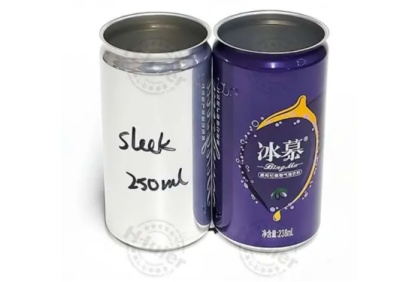

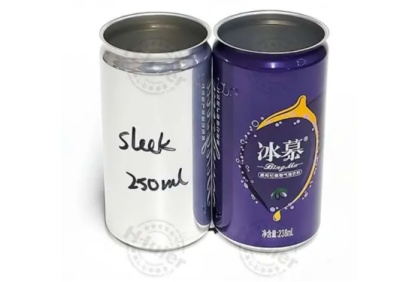

Sleek and Slim Cans

Slim cans are increasingly used for:

Energy drinks

Sparkling beverages

Nutritional drinks

Premium water

Their stylish profile differentiates products and appeals to health-conscious consumers.

Bottled Cans (Aluminum Bottles)

Aluminum bottles combine the durability of cans with the re-sealability of bottles. They are suitable for beverages like:

Cold brew coffee

Wine

Functional drinks

Sports beverages

Their premium feel makes them attractive to upscale brands.

4. Aluminum Cans vs. Other Beverage Packaging Materials

Aluminum vs. Plastic (PET)

Feature | Aluminum Cans | PET Bottles |

Recyclability | 100%, infinite | Limited cycles |

Light protection | Excellent | Poor |

Carbonation retention | Superior | Moderate |

Branding | Full-body printing | Label-dependent |

Environmental perception | Very positive | Often negative |

Aluminum clearly outperforms PET in sustainability and product protection, though PET remains popular for low-cost, non-carbonated drinks.

Aluminum vs. Glass

Feature | Aluminum Cans | Glass Bottles |

Weight | Very light | Heavy |

Breakage risk | None | High |

Transportation cost | Low | High |

Shelf appeal | Modern | Premium/traditional |

Recyclability | High | High |

Glass offers premium aesthetics but is becoming less practical for large-scale beverage distribution due to weight and fragility.

Aluminum vs. Cartons / Pouches

Cartons and flexible pouches are cost-effective but lack the durability, recyclability, and protective performance of aluminum cans.

5. The Role of Aluminum Cans in Emerging Beverage Trends

Functional Beverages and Energy Drinks

Energy drink brands pioneered the use of slim aluminum cans, establishing them as the “standard look” for high-energy, performance-focused beverages. The lightweight, modern appearance aligns with the lifestyle image these brands promote.

Ready-to-Drink (RTD) Coffee and Tea

RTD coffee and tea beverages require protection from oxygen and light to maintain freshness. Aluminum cans provide a highly stable environment, which has encouraged major brands to shift from PET bottles to cans.

Alcoholic Beverages and Craft Drinks

Beyond beer, canned cocktails, wine spritzers, and hard seltzers are growing rapidly. Aluminum cans are ideal for these products because they:

The craft beer industry, in particular, has embraced aluminum due to its recyclability and branding surface.

Premium Water

High-end water brands have begun introducing aluminum cans and bottles to appeal to environmentally conscious consumers who seek a plastic-free alternative.

![hiuierpack hiuierpack]()

6. Manufacturing Process of Aluminum Cans

Producing aluminum cans involves several stages:

Aluminum Sheet Production

High-quality aluminum sheets are rolled to precise thicknesses.

Cup Forming

Circular blanks are stamped into shallow cups.

Drawing and Ironing

The cups are drawn multiple times to form tall, thin-walled can bodies.

Trimming

The tops are trimmed to uniform height.

Washing and Coating

Cans are thoroughly cleaned and coated internally with food-grade linings to prevent interaction with beverage contents.

Printing and Decorating

High-speed printing lines apply artwork and logos around the entire can surface.

Necking and Flanging

The top of the can is narrowed to accept a can end.

Quality Inspection

Cans undergo pressure testing, leak detection, and visual inspection.

This highly automated process ensures consistency, hygiene, and efficiency at massive production volumes.

7. Sustainability Initiatives Driving Aluminum Can Adoption

Global beverage companies are setting ambitious environmental goals. Aluminum cans help them achieve targets such as:

Reducing plastic waste

Increasing recycled content in packaging

Lowering greenhouse gas emissions

Supporting circular economy principles

Many countries and regions have implemented deposit-return schemes (DRS) that significantly increase aluminum recycling rates. These programs reinforce consumer habits and close the loop on material recovery.

8. Challenges and Considerations in Aluminum Can Packaging

Despite their advantages, aluminum cans come with certain considerations:

Impact on Beverage Taste (Rare but Possible)

Improper lining or damage to the interior coating can cause slight off-flavors. However, modern coating technologies have nearly eliminated this issue.

Price Volatility

The cost of aluminum can fluctuate depending on global commodity markets. Brands must manage long-term contracts to stabilize supply and pricing.

Manufacturing Energy Requirements

While recycled aluminum requires little energy, producing fully new aluminum (primary aluminum) is energy-intensive. This makes recycling especially vital.

9. The Future of Aluminum Cans in Beverage Packaging

The future of beverage packaging is increasingly shaped by sustainability, technology, and consumer preferences. Aluminum cans are well-positioned due to their environmental strengths and versatility. Future developments may include:

Higher recycled content in can production

Advanced inks and coatings for better shelf stability

Smart packaging, such as QR-coded cans for traceability

Lightweighting innovations to reduce material usage

Expanded use in emerging beverage categories, including plant-based drinks and health elixirs

As global awareness of environmental issues grows, aluminum cans are expected to remain a leading choice in beverage packaging for decades.

Conclusion

Aluminum cans have proven themselves as one of the most reliable, sustainable, and consumer-friendly solutions in beverage packaging. Their unmatched recyclability, excellent product protection, and branding flexibility make them essential to the modern beverage landscape. Whether for carbonated drinks, energy beverages, functional drinks, RTD teas, coffee, or premium water, aluminum cans deliver the performance and environmental benefits that today’s market demands.

For businesses seeking high-quality aluminum can products or exploring customized beverage packaging solutions, Hainan Hiuier Industrial Co., LTD. offers professional manufacturing capabilities and reliable supply support. To learn more—or to discuss how their products can meet your packaging needs—you can visit their company website or reach out for further information.